28.04.25PI_609

HG GRIMME SysTech: TIER 1 supplier ACE significantly reduces setup times in CFRP post-processing

Carbon dusts pose a major challenge

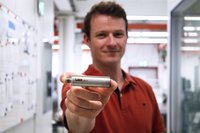

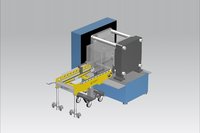

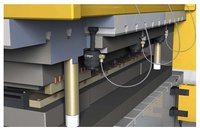

Wiedergeltingen/Germany, April 28, 2025. Two tables with shuttles instead of just one: By switching to new CNC machining centers, ACE has significantly reduced setup times for milling operations on CFRP components. Machine downtime now amounts to a maximum of only three percent, down from up to 45% previously.

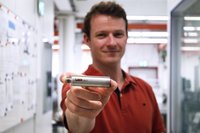

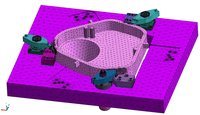

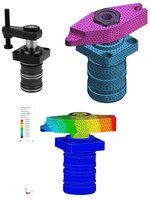

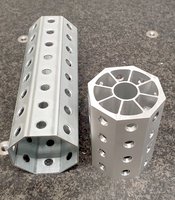

The TIER 1 supplier primarily manufactures carbon fiber reinforced plastic (CFRP) parts for premium automotive manufacturers. They primarily source Class-A quality visible parts and structural components made of CFRP from ACE, which require milling of contours and trims prior to painting. For this purpose, the company from Lake Constance utilizes three 5-axis CNC portal milling machines of the type P-S-F (20-25)/S from HG GRIMME SysTech.

Easy Switching Between Identical Machines

ACE acquired the identical machining centers, each with two tables and a shuttle as well as a Siemens 840d sl control system, between 2016 and 2024. Consistent operation and machine tables with the same hole pattern and a fixed zero point also contribute to short setup times. Furthermore, ACE can post-process the CFRP parts on all machines from HG GRIMME SysTech interchangeably and without any quality limitations.

To download the complete press release and picture in print quality, please press next button.